Achievements of Biochar Application for Enhanced Anaerobic Digestion a Review

Effect of Alfalfa-Derived Biochar on Anaerobic Digestion of Dairy Manure

one

Texas A&M AgriLife Research Center, Section of Biological and Agronomical Engineering, Texas A&M University, College Station, TX 77843, Us

2

Department of Engineering science and Information science, Tarleton Country University, Stephenville, TX 76401, USA

3

Department of Wildlife, Sustainability, and Ecosystem Sciences, Tarleton Country University, Stephenville, TX 76401, The states

*

Writer to whom correspondence should be addressed.

Academic Editor: David Houben

Received: 24 February 2022 / Revised: 11 March 2022 / Accustomed: 6 April 2022 / Published: 11 Apr 2022

Abstruse

Biochemical methane potential (BMP) tests were conducted for investigating the effects of alfalfa-derived biochar (AF-BC) on anaerobic digestion (AD) of dairy manure under various loading of AF-BC (0–ten g/L). BMP tests were performed at mesophilic temperature (37 °C) with the improver of AF-BC. Biogas and marsh gas volumes and concentrations, water quality parameters (i.e., COD (chemical oxygen demand)), and volatile fat acids (VFAs) were measured during the AD process. The addition of ane and 5 yard/L of AF-BC increased the biogas yields by 15.51% and 26.09% and methane yields by 14.61% and 26.88% compared with the control without improver of AF-BC. Additionally, the add-on of AF-BC (ane–10 thousand/L) decreased the lag phase past 7.xiv–22.45% and the COtwo content of biogas by 13.sixty–32.48%, while increasing the COD removal efficiency by xix.19–35.94% in the Advertisement of dairy manure. Moreover, the addition of AF-BC also decreased total VFAs and acetic acid concentrations in the Ad process. The increment in AD performance was mainly owing to the comeback of buffering power of the AD organisation and direct interspecies electron transfer (DIET) amid AD microorganisms resulting from the addition of AF-BC. In dissimilarity, the addition of x thousand/Fifty AF-BC did non show any obvious improvement in biogas and methane yields in the AD of dairy manure, possibly because of toxic furnishings from excessive addition of AF-BC toward the AD microorganisms. Therefore, this study supported practical feasibility of AF-BC-enhanced AD of dairy manure.

1. Introduction

Anaerobic digestion (Advertisement) has been widely used every bit a sustainable route to convert various waste material to biogas and digestate as fuel and biofertilizer while mitigating environmental problems and greenhouse gas emission [one,2,3,iv]. A large quantity of animal manures (nigh 132 million metric tons of dried manure per yr in United States) has been used as the major feedstock for Advertising [5,half dozen]. Dairy manure, amid the animal manures, is generated past upwards to 9.4 meg dairy cows each year [7] and has acquired increasing pollution in soil, water and air when it has been applied to farms as a fertilizer [8]. Therefore, effective Advertizement of dairy manure has been considered as a sustainable remediation procedure for production of renewable energy (either cleaned biogas or renewable natural gas), effective disposal of manure, and reduction of manure-derived greenhouse gas emission [9]. To date, a substantial number of works about Advertisement of dairy manure accept been reported. Li et al. [five] conducted Ad tests with diary manure nether diverse substrate concentrations and achieved a methane yield up to 270 mL/g VS. Zheng et al. [10] evaluated the impact of co-digestion ratios on the functioning of Advert in mixtures of dairy manure and switchgrass, and found that the optimal methane production (155.1 mL/g VS) was observed under a two:2 mixture ratio of manure to grass. In addition, Zeng et al. [11] applied mechanical refining pretreatment to the procedure of Advertizing of dairy manure and improved biogas and methane yields by six% and 8%, respectively.

Nonetheless, AD of dairy manure suffers from inconsistent and fluctuating performance, low yields of biogas, and the need to dispose of a large volume of undigested sludge afterwards AD [12,thirteen]. For enhancing Advertizing functioning, a multifariousness of carbon additives have been applied for the AD procedure, including activated carbon, carbon nanotube, graphene, and carbon material [fourteen]. Carbon nanotubes have improved electrical conductance of substrates and have accelerated the substrate consumption and methyl hydride production rates in the Advertisement of granular sludge [15]. Carbon fabric enhanced the AD of incineration leachate by lowering VFAs level and preventing a significant drop in pH [16]. Graphene was also used for increasing direct interspecies electron transfer (DIET) between electron-agile bacteria and methanogens, increasing methane product in the AD of ethanol [17]. Similarly, activated carbon (AC) besides improved methane production through enriching the Methanosaeta/Methanosarcina species on AC and accelerating the Diet in the AD of activated sludge [18]. Nevertheless, these carbon additives required their disposal after employ and high production costs, limiting their practical application. Thus, development of cost-effective and environmentally friendly additives practical in the AD procedure is highly recommended.

Recently, biochar (BC), fabricated from pyrolyzing the biomass in oxygen-limited conditions, has been considered as an effective carbon additive for improving AD operation [19,twenty,21]. BC can offer a benign surround for microbial zipper and growth, resulting in the comeback of activity of Advert microorganisms [22]. In addition, BC could relieve drastic pH drops from VFA accumulation and reduce ammonia inhibition during the AD procedure [23]. Moreover, BC can human activity equally a microbial support to immobilize microbial cells and act every bit a conductive medium for facilitating the Nutrition between VFAs-oxidative bacteria and methanogens [19]. To date, considerable research for the effects of various BCs on AD has been reported. For example, Pan et al. [iv] establish that, during Advertisement of chicken manure, fruitwood biochar increased the methyl hydride yield past 69% while reducing the ammonia concentration and improving the buffering chapters. Wang et al. [24] added vermicompost-derived BC into the Advertisement of easily acidified substrates and found that BC can offer excellent buffering capacity to hold dorsum a pH drop and cause a significant increment in methane production. In addition, Jang et al. [25,26] showed that the BC derived from dairy manure accomplished a 24.90% increase in marsh gas production and a 36.84% decrease in the lag stage during the mesophilic AD of dairy manure.

Conversely, grass alfalfa (AF), 1 of the extensively grown forage grasses in the US (near 56 million tons per year), is normally used as a hay at dairy farms [27]. In add-on, because of its loftier provender nutritive value and dry out matter yield, AF is also widely planted and important for forage production around the world [28]. Yet, the molds are hands generated at the surface of hay during storage, and approximately xx% of hay is commonly moldy and discarded to avoid harmful effects on beast health [29]. Therefore, AF is a feasible choice as feedstock for BC production due to high output of the AF, especially discarded ones available at dairy farms. Several studies have focused on the production of bio-oil and BC by pyrolyzing AF and used AF-derived BC for treatment of organic contaminants [27,30,31,32]. Still, no research to appointment has focused on producing and applying AF-derived BC for enhancing Advertising of dairy manure. Recycling of discarded AF to AD of dairy manure could enhance environmental and agricultural sustainability at dairy farms.

To the best of our knowledge, for the first time, this study evaluated the feasibility for the application of AF-derived BC for enhancing the AD of dairy manure. In the nowadays piece of work, the effects of AF-derived BC with various loading rates on biogas and marsh gas production were examined along with monitoring of AD metabolites and water quality in the AD of dairy manure. On the ground of changes of biogas production, metabolites, and water quality, possible roles of AF-derived BC in the AD process were discussed.

2. Materials and Methods

2.ane. Substrate and Inoculum

Dairy manure utilized in the present piece of work was obtained from Southwest Dairy Eye at Tarleton Country University (Stephenville, TX, USA). Earlier Advertisement experiments, the manure was dried at 65 °C, basis, and sieved (below 500 µm). The elemental compositions of dried dairy manure were C (16.6%), H (two.iii%), O (31.0%), N (1.1%), S (0.two%), and ash (48.8%) [25]. The inoculum sludge was obtained from the lagoon bottom at Tarleton dairy farm. The collected sludge was activated via cultivating with dairy manure at mesophilic and anaerobic weather condition for about a month [25]. Then, the activated sludge was utilized as the inoculum to conduct AD tests for farther. The major backdrop of the inoculum obtained in the present work included pH at 7.72 ± 0.07, total solids (TS) at 29.92 ± 0.16 1000/L, volatile solids (VS) at fourteen.55 ± 0.16 grand/L, full COD (TCOD) at 17.l ± ii.12 k/Fifty, soluble COD (SCOD)at 0.53 ± 0.01 g/L, total VFAs (TVFAs) at 199 ± 9 mg/L, and total alkalinity (TA) at 939 ± 53 mg CaCO3/Fifty.

2.2. Grooming and Characterization of BC

The grass alfalfa (AF), obtained from a local hay vendor (Stephenville, TX, USA), was used equally the feedstock for BC. Afterward beingness stale, ground, and sieved (<500 µm), x thousand of dry AF was placed into a quartz-tube furnace (MTI corporation, Richmond, VA, USA) for pyrolysis. In order to lower the production price of BC, AF was pyrolyzed at a low pyrolysis temperature. The pyrolysis conditions were set at 350 °C with the heating rate of 10 °C/min and heating time of 120 min under continuous flow of nitrogen gas (2 50/min). The resulting BC was named as "AF-BC". Then, AF-BC was milled and sieved until the particle size was less than 106 µm. The analysis of elemental and mineral compositions of AF and AF-BC was conducted at Robert Microlit Lab (Ledgewood, NJ, USA) and the Soil, Forage and H2o Testing Lab at Texas A&Yard AgriLife (College Station, TX, Usa), respectively. Proximate assay, including stock-still carbon, volatile carbon, and ash, was determined according to ASTM D7582-12 [33]. The surface functional groups of AF-BC were determined via a FTIR Spectrometer (Bruker Optik GmbH, Ettlingen, Germany). The expanse of AF-BC was evaluated by a surface area analyzer (Particle Technology Lab, IL, United states).

2.three. Anaerobic Digestion Experiments

BMP (Biochemical Methane Potential) tests were performed for evaluating the impacts of AF-BC on the Advertizement of dairy manure. Briefly, 130 mL of inoculum and dry dairy manure with a ratio of ane (TS footing) was loaded into a 280 mL serum bottle. The AF-BC was added into the serum bottle with 4 loading rates (0, 1, five, and 10 g of BC/L of manure). Afterward inoculation, each serum bottle was sealed with a rubber plug and a screw cap. Then, North2 gas was flushed into each bottle for removing oxygen and ensuring anaerobic condition in each bottle. All bottles, in replicate, were incubated at mesophilic temperature (37 °C) and manually mixed every 24-hour interval. In this written report, the BMP tests were carried out for 36 d. The experiment sets are referred to every bit command, A1, A5, and A10. The command represents the experiment group without improver of AF-BC, while A1, A5, and A10 represent the addition of 1, 5, and 10 m of AF-BC/L of manure. The experiment setup is shown in Figure S1.

two.4. Analytical Methods

TS, VS, pH, TCOD, SCOD, NH3-Due north, POfour three−, and TA were analyzed via APHA standard methods [34] and commercial test kits (Hach Company, Loveland, CO, USA). The biotoxicity tests of leaching solution from the addition of various concentrations of AF-BC (0–10 g/L) into DI water was conducted using a Toxi-ChromoTestTM kit (Environmental Bio-Detection Products Inc., Mississauga, ON, Canada) [35]. The biogas volume was evaluated using a 60 mL syringe, and marsh gas and carbon dioxide contents of biogas were determined through the gas chromatograph (GC) (GC-2014, Shimaza Corp., Kyoto, Nippon) continued with a packed column, a thermal conductivity detector (TCD) and a flame ionization detector (FID). The concentrations of VFAs were also determined past the GC as previously described [25]. The FID temperature was 250 °C, and the carrier gas was helium.

ii.5. Modified Gompertz Model

For examining the touch on of AF-BC addition on lag phase, maximum production potential and production rate from Advertizing of dairy manure in the electric current work, the methane production data from the AD tests were fitted to a modified Gompertz model shown in the following equation [4,25]:

where M(t) represents the methane yield in a time t (mL/yard VSremoved), P represents the maximum methane potential (mL/thousand VSremoved), Rmax represents the maximum methane product rate (mL/g VSremoved·d), λ represents the lag phase (d), and e is the Euler's constant (2.7183). In the present report, the fitting precision of the model was determined through the conclusion coefficient (R 2):

where Me , Yardc , and Gmean represent the experimental value, calculated value, and mean of experimental value, respectively.

3. Results and Discussion

iii.1. Effects of AF-BC Addition on Methane and Biogas Production

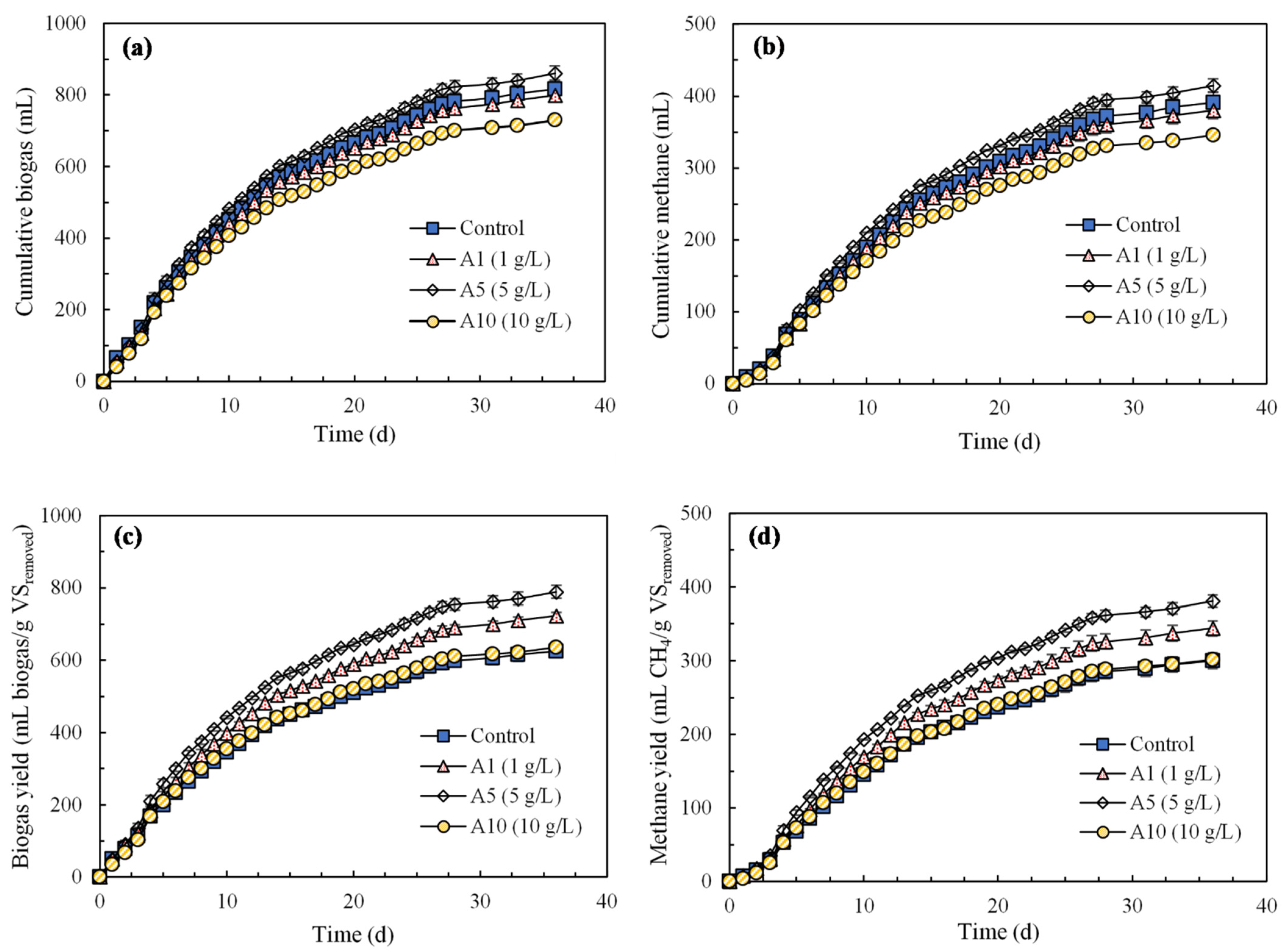

Biogas and marsh gas production from the Ad of dairy manure with diverse loading rates of AF-BC are displayed in Figure 1. The highest cumulative biogas and marsh gas product in the Advertizing of dairy manure was accomplished with the addition of 5 g/L (A5) of AF-BC (Figure 1a,b). Notwithstanding, compared to the control, the add-on of 10 m/L (A10) of AF-BC to the Advertizing of dairy manure showed negative effects on cumulative biogas and methane volumes, probably due to the potential biotoxicity from AF-BC add-on, which is described in Section 3.two. Conversely, the biogas yields in A1 and A5 were improved past xv.51% and 26.09%, respectively, compared to the control (625.99 mL/g VSremoved) (Figure 1c). Similarly, the methyl hydride yields in A1 and A5 increased by fourteen.61% and 26.88%, respectively, compared to the control (300.01 mL/g VSremoved) (Figure 1d). Therefore, compared to the control, the addition of AF-BC (1–five g/50) to the Advert of dairy manure resulted in finer enhancing biogas and methane production. Every bit shown in Tabular array S1, these results were remarkably consistent with the positive impacts of BC on methane and biogas production reported by previous studies [4,36]. Wei et al. [37] evaluated the impacts of corn stover-derived BC on the Advertising of primary sludge and found that BC significantly improved the methyl hydride yield by eight.6–17.eight%. Pan et al. [4] conducted the AD of craven manure with the addition of 9 different kinds of BCs, and the results showed that all BCs significantly improved methyl hydride yields, and the addition of fruitwood-derived BC achieved a marsh gas yield of 294 mL/g VS. Moreover, the AD of sewage sludge and orangish peels carried out by Martínez et al. [36] indicated that 10 g/L of vineyard pruning-derived BC improved the methyl hydride yield by 33% in the batch digestion system.

However, the addition of 10 g/L of AF-BC (A10) showed no obvious improvement of methyl hydride and biogas yields compared with the command. The biogas and methane yields of A10 were 641.70 mL/grand VSremoved and 301.68 mL/1000 VSremoved (Figure 1), which were lower than those of A1 and A5, with almost no difference from the control, indicating that a high loading rate of AF-BC was not favorable for the Advertising of dairy manure. Similar results have also been observed past Shen et al. [2], Shen et al. [38], and Sunyoto et al. [39]. Shen et al. [2] found that CHiv yield from the Ad of mixtures of straw and cattle manure increased from 267.55 to 281.48 mL/m VS with the addition of coconut vanquish-derived BC at a 2% loading rate. However, the CHiv yield was reduced to 271.5 mL/g VS with 4% loading of the BC, mainly because of the aggregating of higher concentrations of acidic intermediates resulting in the imbalance of the Advertizing system. Shen et al. [38] likewise reported that the high loading rates of woods-derived BC to the AD of primary sludge showed no significant divergence for methane production compared to the control due to possible inhibition of microbial activities amidst AD microorganisms. Moreover, Sunyoto et al. [39] investigated the 2-stage AD procedure using nutrient waste with the addition of sawdust-derived BC. The results indicated that increasing loading rates of the BC ranging from 8.3–33.3 g/L caused a decrease in methane product. It was found that the addition of BC at loftier loading rates caused a significant aggregating of propionic acid, which could inhibit methane production [39].

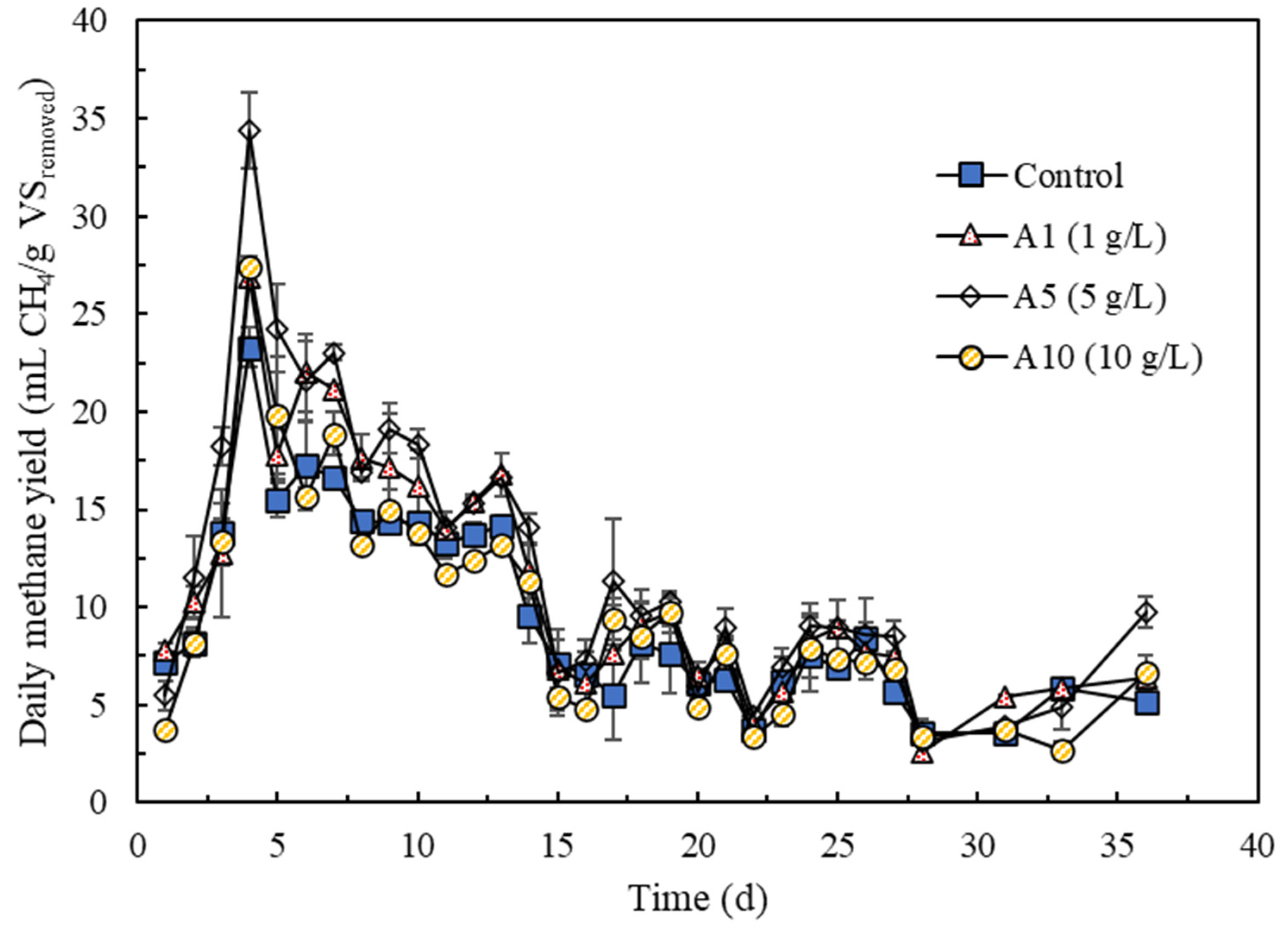

Every bit displayed in Figure 2, the first daily methane yield pinnacle appeared on the fourth day of the Advertisement procedure for all experiment groups, which might have been caused by the consumption of easily degradable organic matter past anaerobic microorganisms [4]. The maximum daily methane yields in A1 (26.84 mL/g VSremoved), A5 (34.35 mL/one thousand VSremoved), and A10 (27.45 mL/g VSremoved) were obviously higher than that in the control (23.29 mL/chiliad VSremoved), which means that AF-BC could enhance utilization efficiency of organic substrates in the initial stage of Ad. In addition, the 2nd and third peaks in A5 (17th and 24th solar day) appeared before than those in the control (18th and 26th day), revealing that the addition of AF-BC to the Advert procedure can accelerate the degradation of complex intermediates in the centre and later stages, thus increasing methane production overall [4]. Pan et al. [4] too observed three daily methane yield peaks during the Advertizing of craven manure and indicated that the improver of BC produced methane before than the control without the addition of BC.

In the nowadays study, the experimental data were also fitted to the Gompertz model to develop a microbial kinetic model for the AD of dairy manure with the addition of AF-BC. Table 1 shows that A1 and A5 achieved significantly higher Rmax (mL CH4/1000 VSremoved·d) and P (mL CHfour/yard VSremoved) than the control. Both Rmax and P increased by 17.70% and 13.89% in A1, and 30.86% and 25.lx% in A5, respectively, compared with the control. The results highly agree with positive impacts of BC improver on the methane production rate and yield (Rmax and P) during the AD process [ane,25,40]. For example, Wei et al. [37] showed that both Rmax and P were improved past 53.79% and 13.72% when the corn stover-derived BC was applied to the AD of principal sludge obtained from the WWTP. However, there were no significant differences betwixt the control and A10 for Rmax (xv.20 vs. 15.51 mL/g VSremoved·d) and P (295.78 vs. 297.47 mL/g VSremoved). Shen et al. [38] indicated that a high concentration of woods-derived BC (4.97 grand BC/g dry out sludge) caused the lower Rmax and P than a depression concentration of BC (ii.49 m BC/g dry out sludge). Moreover, Wang et al. [1] also reported that Rmax and P significantly increased during the Advertisement of sludge and nutrient waste with increasing loading of the sawdust-derived BC up to 6 g/L. However, the Rmax and P markedly decreased with loftier loading of BC (more than 6 one thousand/L). In improver, equally noted in Table 1, the lag phase (λ) in AD was shortened later the addition of AF-BC. Compared to the command, λ was reduced by 7.xiv%, 22.45%, and 12.24% nether the add-on of 1, 5, and 10 g/L of AF-BC, possibly owing to faster adaptation and communication of microorganisms with the improver of AF-BC. Similarly, Fagbohungbe et al. [41] applied three kinds of BCs (kokosnoot vanquish BC, rice husk BC, and woods BC) in the process of AD of citrus peel and indicated that all BCs could lower the lag phase of AD. Wang et al. [42] besides constitute that Douglas fir-derived BCs pyrolyzed at 500 and 600 °C led to the decrease in lag phase past 14.29% and 9.52% during Advertisement of wastewater sludge.

3.2. Potential Roles of AF-BC in AD

3.2.1. COD, Ammonia, and Phosphate

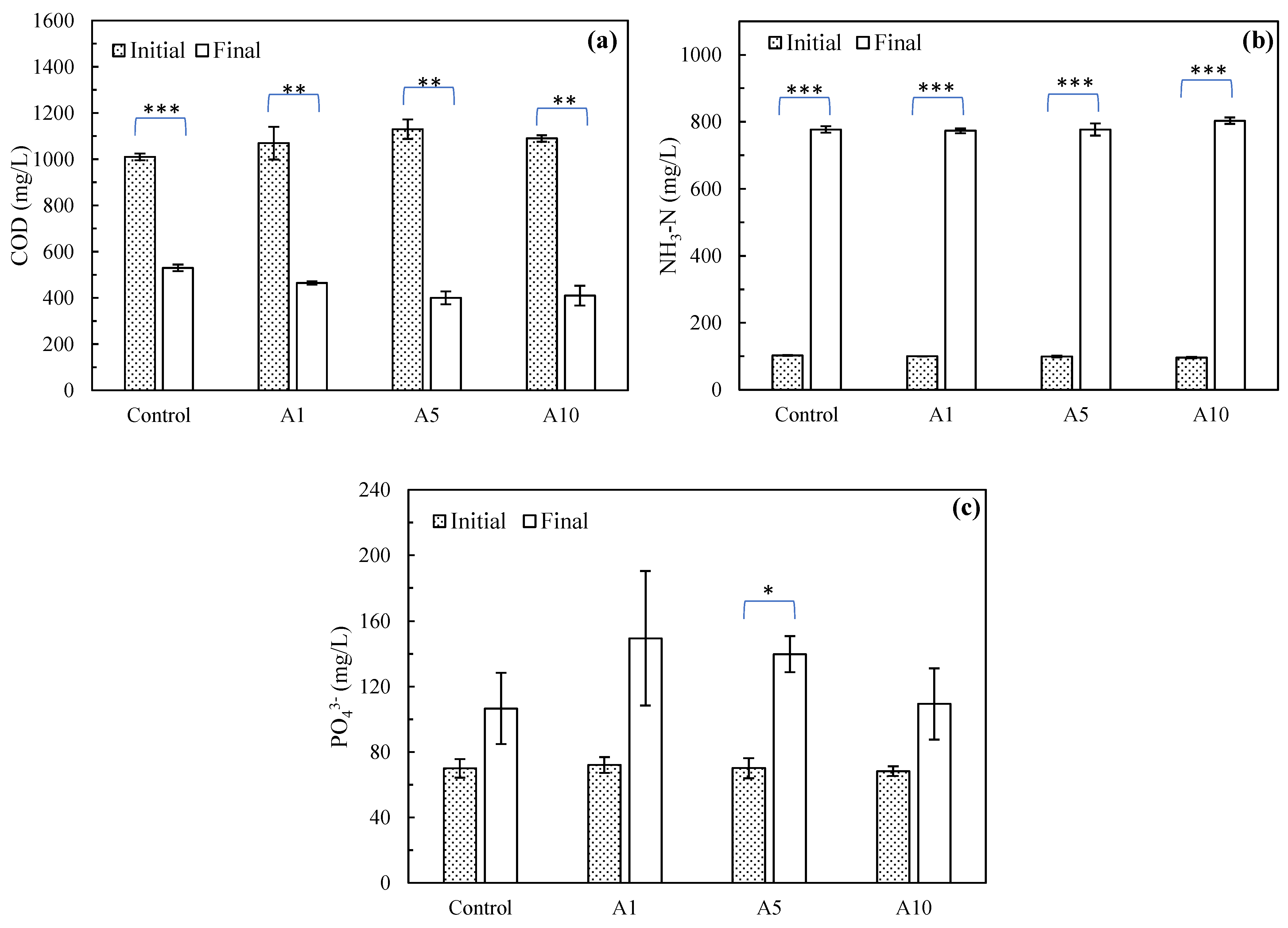

The impacts of AF-BC addition on COD, ammonia, and phosphate removal in the Advertising procedure are presented in Figure three. A1, A5 and A10 achieved COD removal efficiencies of 56.64%, 64.60%, and 62.39% (Figure 3a), which were higher than that of the control (47.52%). This supported that the improver of AF-BC improved COD reduction from the AD of dairy manure. It was thought that microbial activeness of AD tin can increase with the addition of AF-BC to Ad, resulting in a higher consumption of organic compounds in the AD of dairy manure. The outcome was consistent with that reported by Shanmugam et al. [43], showing that switchgrass-derived BC could significantly improve the efficiency of COD removal by 16% during the Ad of glucose. Moreover, Choe et al. [44] added the bamboo-derived hydrochar into the Ad of fish processing waste matter while significantly enhancing COD reduction. However, the COD removal efficiency in A10 (Figure 3a) was comparable to that in A5, revealing that high loading of AF-BC was not favorable for farther COD reduction. One assumption could be that AF-BC might contain some toxic compounds, which were produced during the pyrolysis process, resulting in the negative furnishings on AD microorganism activity due to the high loading of AF-BC. Lyu et al. [45] also reported that toxic compounds such as polycyclic effluvious hydrocarbons (PAHs) and dioxin-compounds were generated during the BC production past pyrolyzing the sawdust at 300 to 700 °C, with a higher toxicity of BC at lower temperatures. In addition, Smith et al. [46] indicated that toxicity of pino wood-derived BCs was mainly from lignin-derived phenolic compounds in BCs, and the toxicity of BCs was higher at a low pyrolysis temperature (300–400 °C). Moreover, in this written report, the biotoxicity of leaching solution of AF-BC showed an increasing trend with an increment in AF-BC concentration from 1 to x g/L (Tabular array S2). Therefore, high loading of AF-BC, produced from pyrolysis of grass alfalfa (containing thirteen% lignin) at low temperature (350 °C), in this written report, might incorporate possible toxic compounds such as PAHs and phenolic compounds, which would be detrimental to AD microorganisms and negatively bear upon the AD process. Thus, this could explain the subtract in methane production with high loading of AF-BC (ten g BC/L, A10 in Effigy 1).

As shown in Figure 3b, after AD, ammonia concentrations significantly increased in all experiment groups, from 96.ii–102.4 to 773–803 mg/L NH3-N, which resulted from effective degradation of nitrogen-containing organic matters by Advertizement microorganisms. Moreover, the concluding ammonia concentrations in A1 and A5 showed no significant difference with that in the command. Notwithstanding, compared to the command, a high dosage of AF-BC (A10) increased the last ammonia concentration from 777 to 803 mg/Fifty. Similarly, Effigy 3c indicates that the Advert with AF-BC also enhanced phosphate concentration due to the enhanced hydrolysis of organic phosphate into inorganic phosphate. The high ammonium and increased phosphate concentrations, after the Advert of manure, could exist valuable sources of liquid biofertilizer when properly irrigated to agricultural farms.

iii.2.ii. CO2 Content

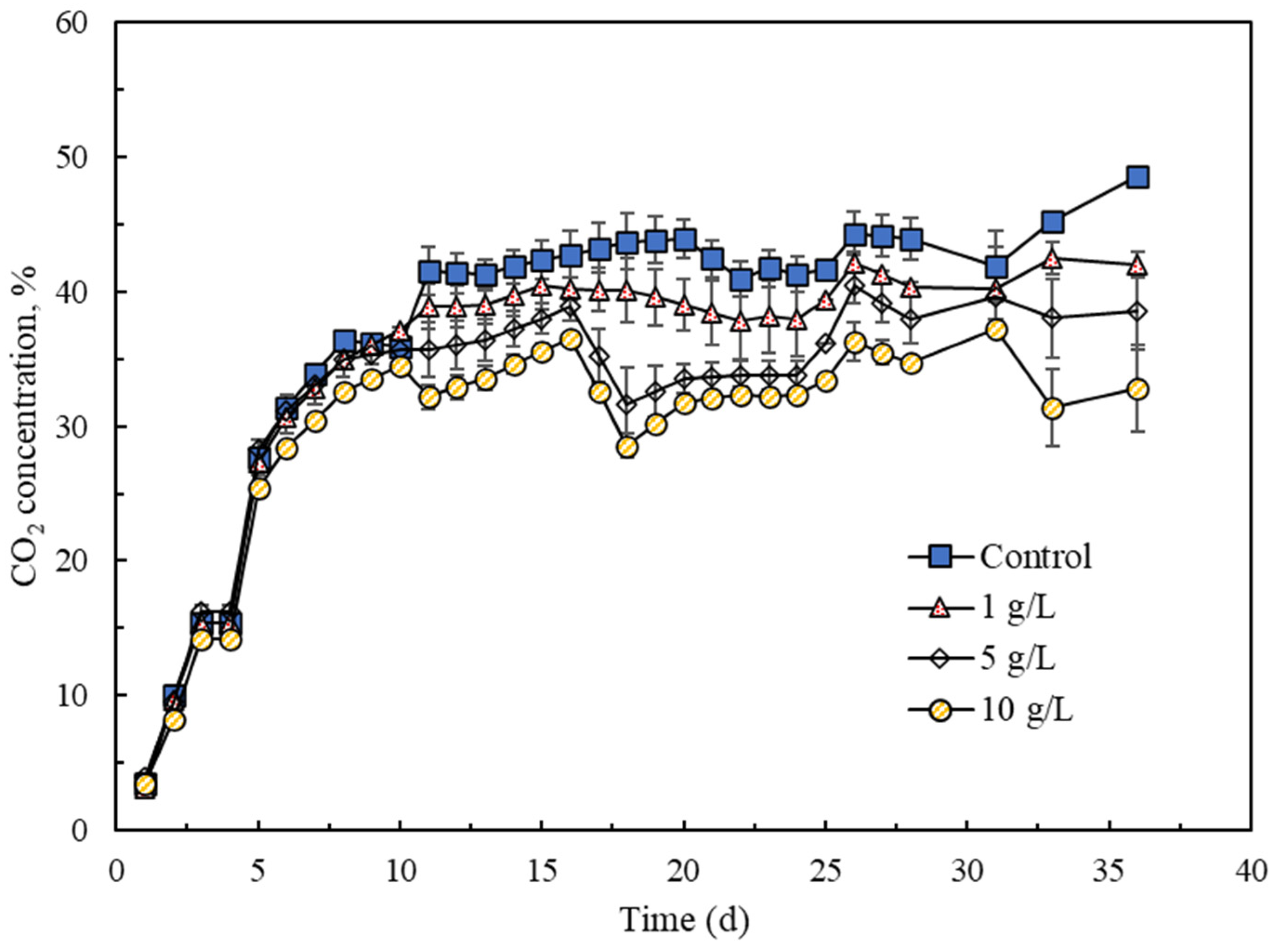

Biogas, produced from the AD procedure, largely consists of methane, carbon dioxide, and other impurities. CO2, considered equally a greenhouse gas, can cause climate change, while college CO2 concentrations issue in the lower free energy value of biogas [47]. Therefore, possibly low amounts of CO2 in biogas are benign for high energy values of biogas and accept a depression touch on on climate change. Figure 4 shows that, after 36 days of Advertizing, the COtwo content of biogas in A1, A5, and A10 decreased from 48.59% to 41.98%, 38.57%, and 32.81% compared to the command, respectively, implying that AF-BC addition was favorable for the reduction of the CO2 content in biogas. In add-on, it is obvious that the COii content in biogas decreased with an increased loading rate of AF-BC. It is well known that BC has the adsorption capacity for CO2 in biogas via physisorption (due east.g., Van der Waals' strength), which could be enhanced by chemical interactions between acidic CO2 and basic nitrogen functional groups of BC [48]. Creamer et al. [49] also mentioned that nitrous groups in the BC played an important role in COtwo adsorption past the BC. Every bit seen in Figure S2, AF-BC contained some nitrous functional groups (C-N and North-O), which was beneficial for CO2 capture in the Ad of dairy manure. Similarly, Baltrėnas et al. [47] conducted the AD of chicken manure with the addition of wood BC and indicated that the addition of forest BC did non result in enhancement for biogas production, only CO2 content decreased from 47.5% to 33.1%.

iii.2.3. VFAs Analysis

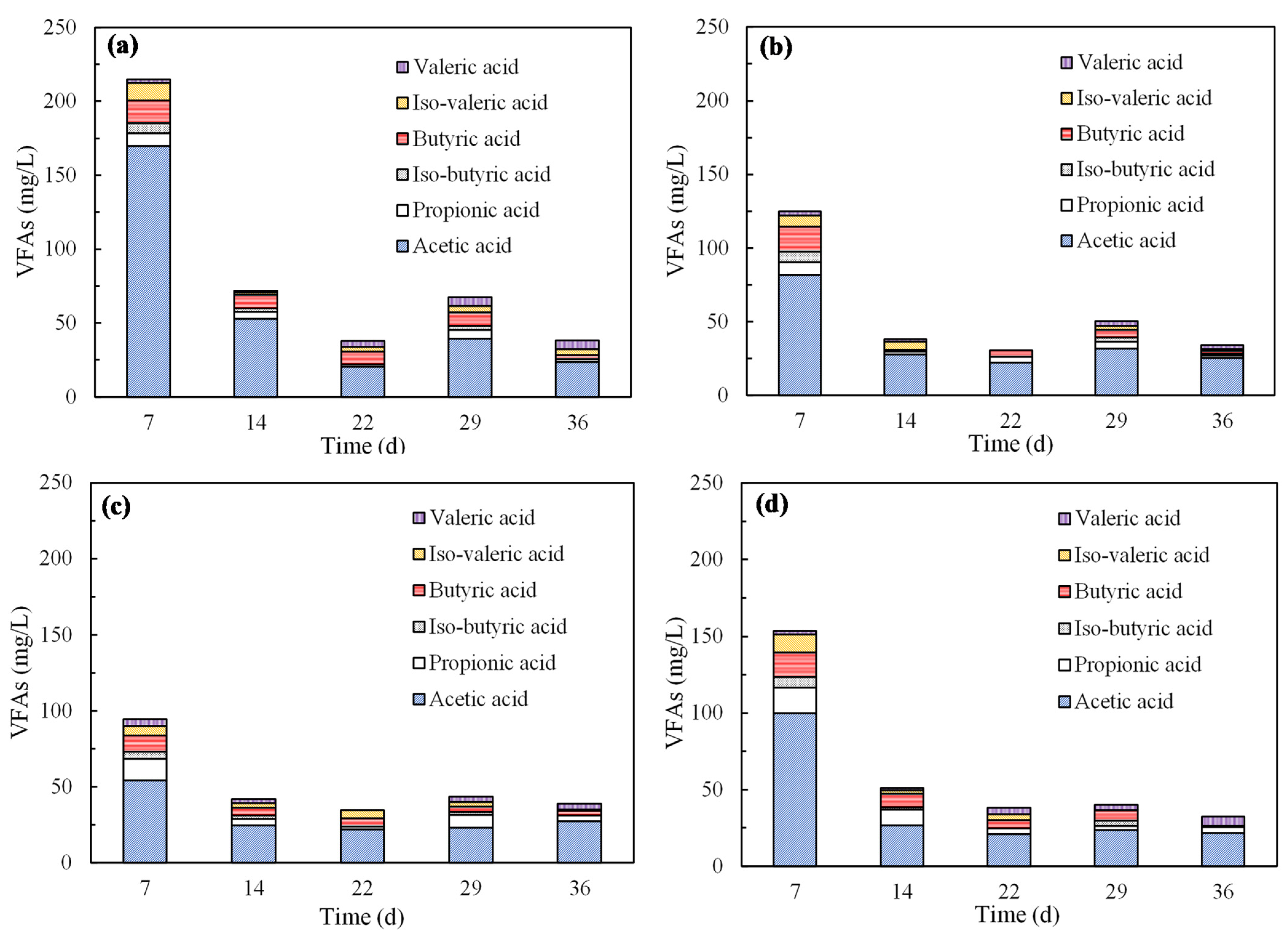

VFAs aggregating during AD processes often causes drastic pH drops and inhibition of microbial activity [nineteen]. Figure five indicates that all experiments in the control, A1, A5 and A10 exhibited a similar trend of full VFAs concentration variation. Total VFAs concentration at 7 d was the highest and then rapidly decreased in all experiments. This is due to the rapid hydrolysis of the easily degradable organic thing in the manure by Advertizing microorganisms at the initial stage. Compared to the command, total VFAs concentration was significantly reduced with the improver of AF-BC. For instance, in the seventh day, total VFAs concentrations in A1, A5, and A10 (124.89, 94.64, and 153.69 mg/Fifty) were lower than the control (214.66 mg/Fifty). Wang et al. [24] and Sunyoto et al. [39] found that the addition of vermicompost BC and sawdust BC to the Ad of craven manure and white bread tin significantly reduce VFAs accumulation and lead to an increase in methane production. In contrast, Pan et al. [23] reported that excess BC could cause an excessive acceleration of hydrolysis and acidogenesis–acetogenesis to an unbearable extent, resulting in an imbalance to the Advertisement system and the aggregating of intermediates, which finally reduced methane production. Therefore, in the present written report, total VFAs concentration in A5 was less than that in A10, which supported the result that high concentrations of AF-BC were not favorable for methane product.

Equally seen in Effigy 5, acetic acrid was the primary VFA from the Advert of dairy manure under all experimental conditions. Acerb acid is i of the primary precursors for methane production and could be directly utilized by acetotrophic methanogens for methane product [19]. Effigy 5 also indicates that the addition of AF-BC led to the decrease in the concentration of acetic acrid, implying that AF-BC could facilitate the transformation of acerb acid to methane and finally improve the methane yield. Lately, Diet has been considered as an constructive pathway for enhancing methane production in the AD procedure [19,23]. Figure S2 shows that AF-BC possessed various functional groups, including C-H, C-O, C-N, Northward-O, and C=C, which are normally related with quinone, phenazine, and hydroquinone moieties [50,51]. In addition, these moieties can human action equally electron shuttles, accepting electrons from microorganisms and donating electrons to microorganisms, which are favorable for the DIET [50,51]. Thus, it tin can exist inferred that AF-BC can heighten the metabolism of acetic acid via the Diet between acetogens and methanogens on the surface of AF-BC, which improved the efficiency of conversion of acetate to marsh gas.

3.2.iv. Total Alkalinity and pH

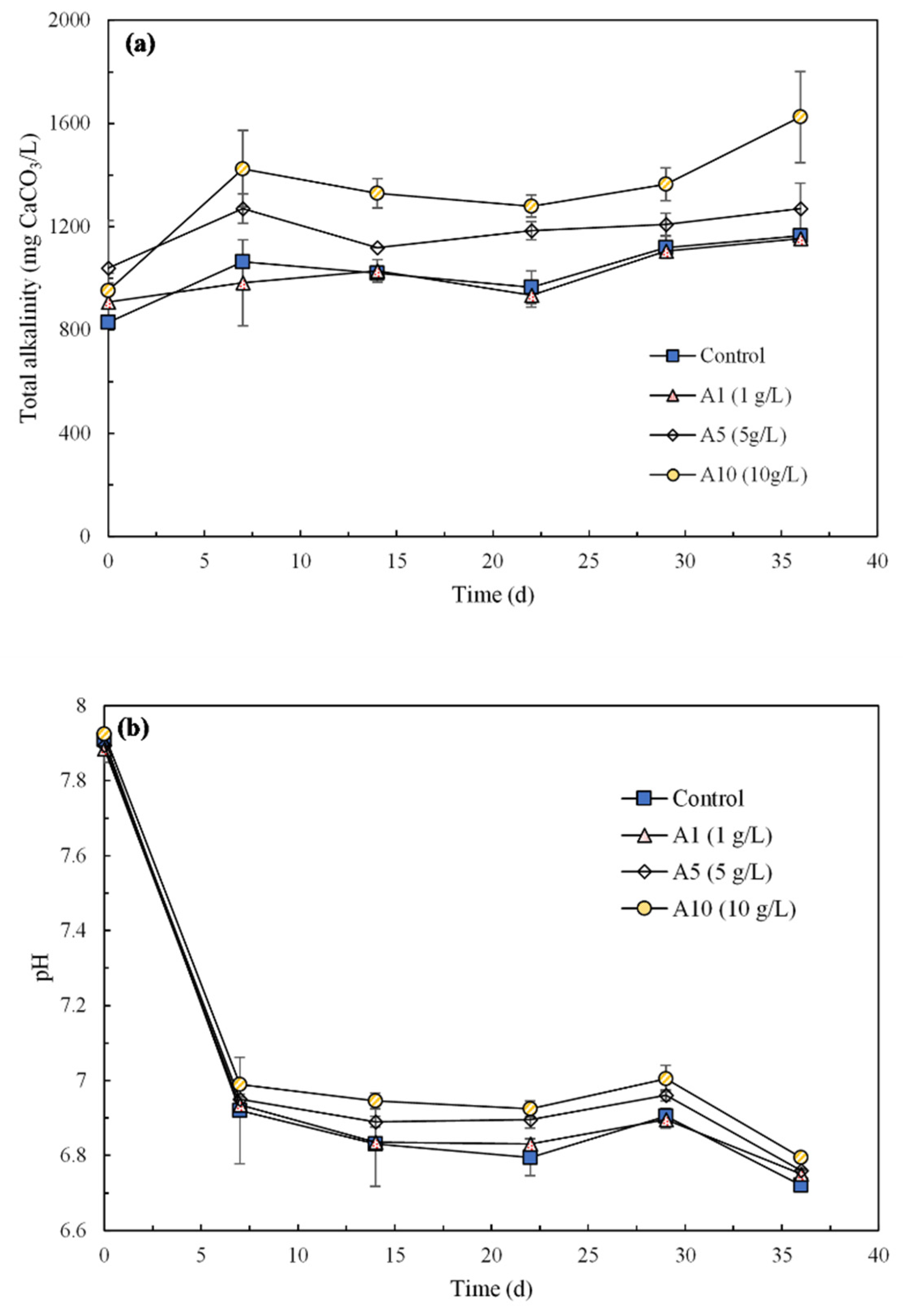

Figure 6a indicates that TA in A1 was comparable to that in the control; nonetheless, TAs in A5 and A10 were much higher than that in the control during the AD process. A college TA concentration with the improver of AF-BC was idea to exist because AF-BC contained diverse brine and alkaline-earth metals such as Chiliad (1 yard/kg BC), Ca (fourteen g/kg BC), and Mg (3 g/kg BC) (Tabular array S3), which endowed the AF-BC with alkalinity properties and buffering abilities in the AD system [4,24]. Moreover, macronutrients such as North (49 g/kg) and P (2 one thousand/kg) in AF-BC (Table S3) also played an important function as buffering agents in the Advertisement system [3,iv]. Therefore, Figure 6b also shows that the pH values in the AD of dairy manure with the improver of AF-BC increased compared to the control. Wang et al. [24] as well mentioned that vermicompost BC increased the buffering chapters to avoid drastic reduction of pH attributable to a high accumulation of VFAs and maintaining loftier activity of Advertizing microorganisms during the Advert of kitchen wastes and chicken manure, while resulting in an increase in Advertizing operation and methane production. In this study, the increased TA concentration resulted in college pH and OH− ions, which reacted with CO2 to produce CO3 two− or HCOiii −. Both CO2 and CO3 two−/HCO3 − could deed as the electron acceptors and were reduced to methyl hydride by hydrogenotrophic methanogens [52,53]. Therefore, the increment in TA and pH values due to the improver of AF-BC could facilitate the maintenance of CO2 in the form of CO3 two−/HCO3 − in aqueous solution, which enhanced the COii utilization for methane product [25,52]. Thus, based on the results from this written report, the addition of AF-BC at a moderate loading rate (or advisable loading rate) could significantly ameliorate the performance of AD of dairy manure. Future works will focus on analyzing microbial communities and the understanding of possible mechanisms associated with the Advertizing of dairy manure with the addition of AF-BC.

4. Conclusions

The effects of AF-BC on the Advertizement of dairy manure were examined in the nowadays study. The Advert of dairy manure with the addition of AF-BC at i–5 g/Fifty showed a significant enhancement of biogas and methyl hydride production compared to the control. The biogas and marsh gas yields during the Ad of dairy manure increased by fifteen.51% and xiv.61%, with the addition of 1 1000/50 AF-BC, and 26.09% and 26.88% with the add-on of 5 thousand/Fifty AF-BC. The main reasons for the increment in AD operation were that the addition of AF-BC improved the buffering ability of the Advertisement system and Diet betwixt Advertising microorganisms. All the same, the addition of AF-BC at 10 g/L was non favorable for methane production, possibly owing to toxicity of AF-BC at high loading. Besides, the add-on of AF-BC also reduced the lag stage and VFAs concentrations while increasing total alkalinity in the AD process. Overall, this written report provides valuable information for application of AF-BC in the enhancement of AD of dairy manure. This sustainable reuse of various wastes (waste product hay, manure) at dairy farms through interaction of biochar and Advert could significantly raise environmental and agricultural sustainability at dairy and other animal farms.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/agronomy12040911/s1, Table S1: Summary of effects of various biochars on methane production during anaerobic digestion [54,55]; Table S2: The biotoxicity of leaching solutions of AF-BC at diverse concentrations; Table S3: The physicochemical characteristics of AF and AF-BC; Figure S1: Experiment set-up for anaerobic digestion of dairy manure with the improver of AF-BC; Figure S2: FT-IR spectrum of AF-BC.

Writer Contributions

S.Z. carried out all experiments, analyzed the experimental information, and wrote the original manuscript. R.H. participated in the measurement of biogas during the AD experiments. E.Grand. provided the novel concepts, methodologies, and funding for this inquiry work and revised the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the Texas A&M University Chancellor Research Initiative Fund (435680) and past the US Section of Agriculture (TEX09764, 1022440).

Institutional Review Board Statement

Not applicable.

Informed Consent Argument

Not applicable.

Data Availability Statement

All information reported in this study are independent within the article.

Acknowledgments

We would like to thank the fiscal support from Texas A&M Academy Chancellor Research Initiative Fund, grant number 435680, and the United states Department of Agriculture, grant number TEX09764.

Conflicts of Interest

The authors declare no disharmonize of interest.

References

- Wang, M.; Li, Q.; Gao, X.; Wang, X.C. Synergetic promotion of syntrophic methane product from anaerobic digestion of complex organic wastes by biochar: Functioning and associated mechanisms. Bioresour. Technol. 2018, 250, 812–820. [Google Scholar] [CrossRef] [PubMed]

- Shen, R.; Jing, Y.; Feng, J.; Luo, J.; Yu, J.; Zhao, L. Performance of enhanced anaerobic digestion with dissimilar pyrolysis biochars and microbial communities. Bioresour. Technol. 2020, 296, 122354. [Google Scholar] [CrossRef] [PubMed]

- Romero-Güiza, M.S.; Vila, J.; Mata-Alvarez, J.; Chimenos, J.Grand.; Astals, S. The function of additives on anaerobic digestion: A review. Renew. Sustain. Free energy Rev. 2016, 58, 1486–1499. [Google Scholar] [CrossRef]

- Pan, J.; Ma, J.; Liu, Ten.; Zhai, 50.; Ouyang, X.; Liu, H. Furnishings of dissimilar types of biochar on the anaerobic digestion of chicken manure. Bioresour. Technol. 2019, 275, 258–265. [Google Scholar] [CrossRef] [PubMed]

- Li, One thousand.; Liu, R.; Sun, C. Comparing of anaerobic digestion characteristics and kinetics of iv livestock manures with different substrate concentrations. Bioresour. Technol. 2015, 198, 133–140. [Google Scholar] [CrossRef] [PubMed]

- Dolliver, H.; Kumar, Grand.; Gupta, S. Sulfamethazine uptake by plants from manure-amended soil. J. Environ. Qual. 2007, 36, 1224–1230. [Google Scholar] [CrossRef] [PubMed]

- MacDonald, J.M.; O'Donoghue, E.J.; McBride, Westward.; Nehring, R.; Sandretto, C.L.; Mosheim, R. Profits, Costs, and the Challenging Structure of Dairy Farming/ERR-47; USDA ARS Rep; USDA ERS: Washington, DC, United states of america, 2018. [Google Scholar]

- Hill, D.; Morra, M.J.; Stalder, T.; Jechalke, Due south.; Top, E.; Pollard, A.T.; Popova, I. Dairy manure as a potential source of crop nutrients and environmental contaminants. J. Environ. Sci. 2021, 100, 117–130. [Google Scholar] [CrossRef]

- Flores-Orozco, D.; Patidar, R.; Levin, D.B.; Sparling, R.; Kumar, A.; Cicek, N. Issue of mesophilic anaerobic digestion on the resistome profile of dairy manure. Bioresour. Technol. 2020, 315, 123889. [Google Scholar] [CrossRef]

- Zheng, Z.; Liu, J.; Yuan, X.; Wang, Ten.; Zhu, West.; Yang, F.; Cui, Z. Effect of dairy manure to switchgrass co-digestion ratio on methane production and the bacterial community in batch anaerobic digestion. Appl. Energy 2015, 151, 249–257. [Google Scholar] [CrossRef]

- Zeng, S.; Jang, H.Grand.; Park, South.; Park, S.; Kan, E. Furnishings of mechanical refining on anaerobic digestion of dairy manure. ACS Omega 2021, 6, 16934–16942. [Google Scholar] [CrossRef]

- Chen, Y.; Cheng, J.J.; Creamer, K.S. Inhibition of anaerobic digestion process: A review. Bioresour. Technol. 2008, 99, 4044–4064. [Google Scholar] [CrossRef] [PubMed]

- Yenigün, O.; Demirel, B. Ammonia inhibition in anaerobic digestion: A review. Procedure Biochem. 2013, 48, 901–911. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, W.; Zhang, H.; Wang, Z.; Fan, C.; Zang, L. Recent achievements in enhancing anaerobic digestion with carbon- based functional materials. Bioresour. Technol. 2018, 266, 555–567. [Google Scholar] [CrossRef] [PubMed]

- Li, L.L.; Tong, Z.H.; Fang, C.Y.; Chu, J.; Yu, H.Q. Response of anaerobic granular sludge to single-wall carbon nanotube exposure. Water Res. 2015, lxx, ane–8. [Google Scholar] [CrossRef]

- Lei, Y.; Sun, D.; Dang, Y.; Chen, H.; Zhao, Z.; Zhang, Y.; Holmes, D.East. Stimulation of methanogenesis in anaerobic digesters treating leachate from a municipal solid waste incineration found with carbon cloth. Bioresour. Technol. 2016, 222, 270–276. [Google Scholar] [CrossRef]

- Lin, R.; Cheng, J.; Zhang, J.; Zhou, J.; Cen, G.; Murphy, J.D. Boosting biomethane yield and production rate with graphene: The potential of directly interspecies electron transfer in anaerobic digestion. Bioresour. Technol. 2017, 239, 345–352. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Zhang, Y.; Li, Z.; Zhao, Z.; Quan, Ten.; Zhao, Z. Calculation granular activated carbon into anaerobic sludge digestion to promote methane production and sludge decomposition. J. Clean. Prod. 2017, 149, 1101–1108. [Google Scholar] [CrossRef]

- Qiu, Fifty.; Deng, Y.F.; Wang, F.; Davaritouchaee, M.; Yao, Y.Q. A review on biochar-mediated anaerobic digestion with enhanced methane recovery. Renew. Sustain. Energy Rev. 2019, 115, 109373. [Google Scholar] [CrossRef]

- Zeng, Due south.; Kan, Due east. Chemical activation of provender grass-derived biochar for treatment of aqueous antibody sulfamethoxazole. ACS Omega 2020, 5, 13793–13801. [Google Scholar] [CrossRef]

- Sharma, B.; Suthar, S. Enriched biogas and biofertilizer production from Eichhornia weed biomass in cow dung biochar-amended anaerobic digestion organization. Environ. Technol. Innov. 2021, 21, 101201. [Google Scholar] [CrossRef]

- Wang, Thou.; Li, Q.; Gao, X.; Wang, X.C. Sawdust-derived biochar much mitigates VFAs accumulation and improves microbial activities to enhance methane production in thermophilic anaerobic digestion. ACS Sustain. Chem. Eng. 2018, 7, 2141–2150. [Google Scholar] [CrossRef]

- Pan, J.; Ma, J.; Zhai, L.; Luo, T.; Mei, Z.; Liu, H. Achievements of biochar awarding for enhanced anaerobic digestion: A review. Bioresour. Technol. 2019, 292, 122058. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Ai, J.; Shen, F.; Yang, G.; Zhang, Y.; Deng, S.; Zhang, J.; Zeng, Y.; Song, C. Improving anaerobic digestion of easy-acidification substrates past promoting buffering capacity using biochar derived from vermicompost. Bioresour. Technol. 2017, 227, 286–296. [Google Scholar] [CrossRef]

- Jang, H.Yard.; Choi, Y.K.; Kan, E. Effects of dairy manure-derived biochar on psychrophilic, mesophilic and thermophilic anaerobic digestions of dairy manure. Bioresour. Technol. 2018, 250, 927–931. [Google Scholar] [CrossRef] [PubMed]

- Jang, H.M.; Brady, J.; Kan, East. Succession of microbial community in anaerobic digestion of dairy manure induced by manure-derived biochar. Environ. Eng. Res. 2021, 26, 138–155. [Google Scholar] [CrossRef]

- Jang, H.Thou.; Kan, E. Engineered biochar from agricultural waste for removal of tetracycline in water. Bioresour. Technol. 2019, 284, 437–447. [Google Scholar] [CrossRef]

- McDonald, I.; Baral, R.; Min, D. Effects of alfalfa and alfalfa-grass mixtures with nitrogen fertilization on dry matter yield and forage nutritive value. J. Anim. Sci. Technol. 2021, 63, 305–318. [Google Scholar] [CrossRef]

- Casteel, S.W. Liver disease in cattle induced past consumption of moldy hay. Vet. Hum. Toxicol. 1995, 37, 248–251. [Google Scholar]

- Boateng, A.A.; Mullen, C.A.; Goldberg, N.; Hicks, Thousand.B.; Jung, H.-J.1000.; Lamb, J.F. Production of bio-oil from alfalfa stems by fluidized-bed fast pyrolysis. Ind. Eng. Chem. Res. 2008, 47, 4115–4122. [Google Scholar] [CrossRef]

- Wang, Due south.; Gao, B.; Zimmerman, A.R.; Li, Y.; Ma, L.; Harris, Westward.Yard.; Migliaccio, 1000.West. Physicochemical and sorptive properties of biochars derived from woody and herbaceous biomass. Chemosphere 2015, 134, 257–262. [Google Scholar] [CrossRef]

- Choi, Y.K.; Kan, E. Effects of pyrolysis temperature on the physicochemical backdrop of alfalfa-derived biochar for the adsorption of bisphenol A and sulfamethoxazole in h2o. Chemosphere 2019, 218, 741–748. [Google Scholar] [CrossRef] [PubMed]

- ASTM D7582-12; Standard Exam Methods for Proximate Assay of Coal and Coke by Macro Thermogravimetric Analysis. ASTM: West Conshohocken, PA, United states, 2012.

- APHA. Standard Methods for the Examination of Water and Wastewater; APHA: Washington DC, United states of america, 2005. [Google Scholar]

- Zeng, South.; Kan, E. Thermally enhanced adsorption and persulfate oxidation-driven regeneration on FeCl3-activated biochar for removal of microcystin-LR in water. Chemosphere 2021, 286, 131950. [Google Scholar] [CrossRef] [PubMed]

- Martínez, E.J.; Rosas, J.G.; Sotres, A.; Moran, A.; Cara, J.; Sánchez, M.E.; Gómez, 10. Codigestion of sludge and citrus peel wastes: Evaluating the effect of biochar addition on microbial communities. Biochem. Eng. J. 2018, 137, 314–325. [Google Scholar] [CrossRef]

- Wei, West.; Guo, W.; Ngo, H.H.; Mannina, G.; Wang, D.; Chen, X.; Liu, Y.; Peng, L.; Ni, B.J. Enhanced loftier-quality biomethane production from anaerobic digestion of primary sludge by corn stover biochar. Bioresour. Technol. 2020, 306, 123159. [Google Scholar] [CrossRef]

- Shen, Y.; Linville, J.L.; Ignacio-de Leon, P.A.A.; Schoene, R.P.; Urgun-Demirtas, M. Towards a sustainable paradigm of waste matter-to-energy process: Enhanced anaerobic digestion of sludge with woody biochar. J. Clean. Prod. 2016, 135, 1054–1064. [Google Scholar] [CrossRef]

- Sunyoto, N.M.Due south.; Zhu, Thousand.; Zhang, Z.; Zhang, D. Consequence of biochar addition on hydrogen and marsh gas production in ii-phase anaerobic digestion of aqueous carbohydrates food waste. Bioresour. Technol. 2016, 219, 29–36. [Google Scholar] [CrossRef]

- Cai, J.; He, P.; Wang, Y.; Shao, L.; Lu, F. Effects and optimization of the employ of biochar in anaerobic digestion of nutrient wastes. Waste Manag. Res. 2016, 34, 409–416. [Google Scholar] [CrossRef]

- Fagbohungbe, M.O.; Herbert, B.M.; Hurst, L.; Li, H.; Usmani, Due south.Q.; Semple, K.T. Impact of biochar on the anaerobic digestion of citrus pare waste. Bioresour. Technol. 2016, 216, 142–149. [Google Scholar] [CrossRef]

- Wang, P.; Peng, H.; Adhikari, S.; Higgins, B.; Roy, P.; Dai, W.; Shi, 10. Enhancement of biogas product from wastewater sludge via anaerobic digestion assisted with biochar amendment. Bioresour. Technol. 2020, 309, 123368. [Google Scholar] [CrossRef]

- Shanmugam, Due south.R.; Adhikari, Southward.; Nam, H.; Sajib, Due south.K. Effect of bio-char on methane generation from glucose and aqueous phase of algae liquefaction using mixed anaerobic cultures. Biomass Bioenergy 2018, 108, 479–486. [Google Scholar] [CrossRef]

- Choe, U.; Mustafa, A.M.; Lin, H.; Xu, J.; Sheng, K. Effect of bamboo hydrochar on anaerobic digestion of fish processing waste matter for biogas product. Bioresour. Technol. 2019, 283, 340–349. [Google Scholar] [CrossRef] [PubMed]

- Lyu, H.; He, Y.; Tang, J.; Hecker, M.; Liu, Q.; Jones, P.D.; Codling, G.; Giesy, J.P. Effect of pyrolysis temperature on potential toxicity of biochar if practical to the environment. Environ. Pollut. 2016, 218, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Smith, C.R.; Hatcher, P.G.; Kumar, S.; Lee, J.W. Investigation into the sources of biochar water-soluble organic compounds and their potential toxicity on aquatic microorganisms. ACS Sustain. Chem. Eng. 2016, iv, 2550–2558. [Google Scholar] [CrossRef]

- Baltrėnas, P.; Paliulis, D.; Kolodynskij, V. The experimental study of biogas production when digesting chicken manure with a biochar condiment. Greenh. Gases Sci. Technol. 2019, 9, 837–847. [Google Scholar] [CrossRef]

- Sethupathi, S.; Zhang, M.; Rajapaksha, A.; Lee, S.; Mohamad Nor, Northward.; Mohamed, A.; Al-Wabel, M.; Lee, S.; Ok, Y. Biochars as potential adsorbers of CH4, CO2 and HiiS. Sustainability 2017, 9, 121. [Google Scholar] [CrossRef]

- Creamer, A.E.; Gao, B.; Zhang, Thousand. Carbon dioxide capture using biochar produced from sugarcane bagasse and hickory woods. Chem. Eng. J. 2014, 249, 174–179. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, Z.; Zhang, Y. Enhancing anaerobic digestion of kitchen wastes with biochar: Link between different properties and critical mechanisms of promoting interspecies electron transfer. Renew. Free energy 2021, 167, 791–799. [Google Scholar] [CrossRef]

- Ren, S.; Usman, M.; Tsang, D.C.M.; O-Thong, S.; Angelidaki, I.; Zhu, 10.; Zhang, South.; Luo, G. Hydrochar-facilitated anaerobic digestion: Prove for direct interspecies electron transfer mediated through surface oxygen-containing functional groups. Environ. Sci. Technol. 2020, 54, 5755–5766. [Google Scholar] [CrossRef]

- Shen, Y.; Linville, J.50.; Urgun-Demirtas, Chiliad.; Schoene, R.P.; Snyder, S.West. Producing pipeline-quality biomethane via anaerobic digestion of sludge amended with corn stover biochar with in-situ CO2 removal. Appl. Energy 2015, 158, 300–309. [Google Scholar] [CrossRef]

- Delgado, A.G.; Parameswaran, P.; Fajardo-Williams, D.; Halden, R.U.; Krajmalnik-Brownish, R. Role of bicarbonate every bit a pH buffer and electron sink in microbial dechlorination of chloroethenes. Microb. Cell Fact. 2012, 11, 128. [Google Scholar] [CrossRef]

- Qin, Y.; Wang, H.; Li, X.; Cheng, J.J.; Wu, W. Improving methane yield from organic fraction of municipal solid waste matter (OFMSW) with magnetic rice-harbinger biochar. Bioresour. Technol. 2017, 245, 1058–1066. [Google Scholar] [CrossRef]

- Wu, B.; Yang, Q.; Yao, F.; Chen, S.; He, Fifty.; Hou, Thousand.; Pi, Z.; Yin, H.; Fu, J.; Wang, D.; et al. Part of bicarbonate every bit a pH buffer and electron sink in microbial dechlorination of chloroethenes. Microb. Jail cell Fact. 2012, 11, 128. [Google Scholar] [CrossRef]

Figure i. Cumulative biogas and methane book (a,b) and yield (c,d) from Advertisement of dairy manure with the addition of different concentrations of AF-BC.

Figure 1. Cumulative biogas and methane volume (a,b) and yield (c,d) from AD of dairy manure with the add-on of different concentrations of AF-BC.

Figure 2. Daily methane yield from AD of dairy manure with the add-on of unlike concentrations of AF-BC.

Figure 2. Daily methyl hydride yield from AD of dairy manure with the addition of unlike concentrations of AF-BC.

Effigy 3. COD (a), ammonia (b), and phosphate (c) concentrations before and afterwards AD of dairy manure with the addition of different concentrations of AF-BC. I-way analysis of variance (ANOVA) was performed amidst each group compared (p < 0.05 *, p < 0.01 **, and p < 0.001 ***).

Figure three. COD (a), ammonia (b), and phosphate (c) concentrations before and after Advertising of dairy manure with the addition of dissimilar concentrations of AF-BC. One-manner analysis of variance (ANOVA) was performed among each group compared (p < 0.05 *, p < 0.01 **, and p < 0.001 ***).

Figure 4. Modify of CO2 concentration during AD of dairy manure with the add-on of dissimilar concentrations of AF-BC.

Figure 4. Alter of CO2 concentration during AD of dairy manure with the addition of different concentrations of AF-BC.

Figure v. Changes of VFAs during the Ad of dairy manure with the addition of 0 g/L (a), 1 1000/L (b), 5 g/L (c), and 10 one thousand/L (d) of AF-BC.

Figure 5. Changes of VFAs during the Advertisement of dairy manure with the addition of 0 g/L (a), ane g/L (b), 5 chiliad/Fifty (c), and 10 thousand/L (d) of AF-BC.

Figure 6. Changes of TA (a) and pH (b) during the Advertising of dairy manure with the addition of dissimilar concentrations of AF-BC.

Figure 6. Changes of TA (a) and pH (b) during the AD of dairy manure with the addition of unlike concentrations of AF-BC.

Table 1. Parameter values of modified Gompertz model fitted with the experimental data.

Table 1. Parameter values of modified Gompertz model fitted with the experimental data.

| Biochar Addition | Lag Phase, λ (d) | Rmax (mL CH4/g VSremoved·d) | P (mL CHfour/g VSremoved) | R ii | p Value |

|---|---|---|---|---|---|

| Control | 0.98 ± 0.01 | 15.20 ± 0.12 | 295.78 ± 11.71 | 0.99 | <0.001 |

| A1 (1 one thousand/L) | 0.91 ± 0.17 | 17.89 ± 0.39 | 336.85 ± 11.87 | 0.99 | <0.001 |

| A5 (five chiliad/L) | 0.76 ± 0.08 | 19.89 ± 0.48 | 371.51 ± 9.30 | 0.99 | <0.001 |

| A10 (x 1000/Fifty) | 0.86 ± 0.03 | 15.51 ± 0.24 | 297.47 ± 3.21 | 0.99 | <0.001 |

| Publisher's Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open up access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/past/iv.0/).

Source: https://www.mdpi.com/2073-4395/12/4/911/htm

0 Response to "Achievements of Biochar Application for Enhanced Anaerobic Digestion a Review"

Post a Comment